-

Biorefinery Development

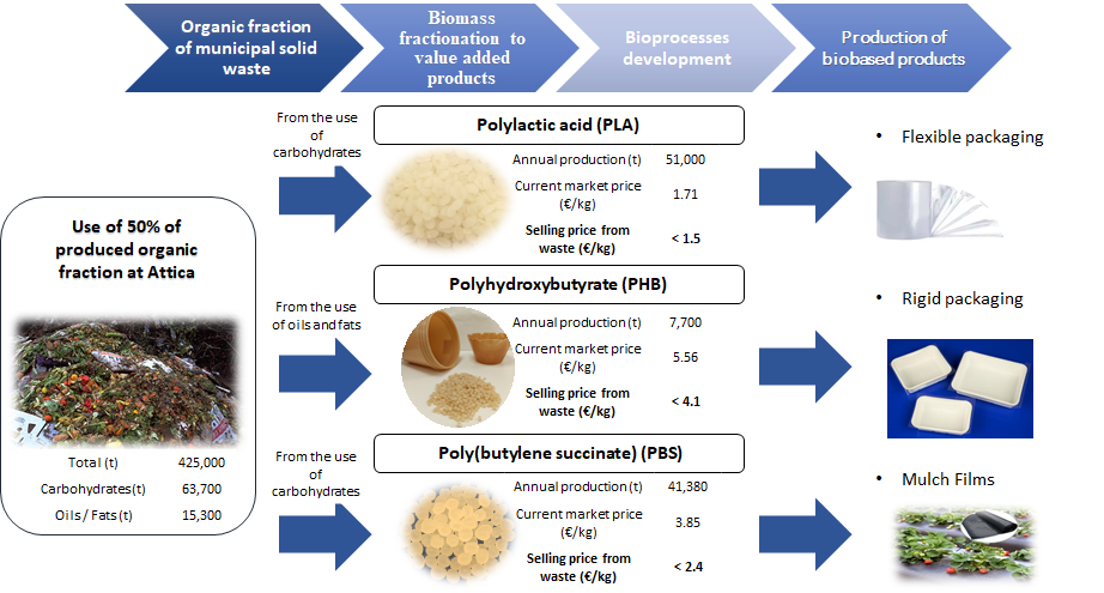

Biorefinery development focuses on refining and bioconversion of agro-industrial and food supply chain side streams (e.g. sugar beet pulp, spent coffee grounds, brewers’ spent grains, winery wastes, spent sulphite liquor, organic fraction of municipal solid waste) into bio-based products. Biomass refining is employed for the recovery of value-added co-products such as antioxidants, oils, proteins, pectins and lignin. The remaining carbohydrate fraction is hydrolyzed using crude enzymes for the production of sugar-rich hydrolysates that are exploited as fermentation feedstocks for the production of chemicals, polymers and other bio-based products (e.g. microbial oil, polyhydroxyalkanoates, organic acids, bacterial cellulose).

The development of sustainable biorefineries necessitates the reduction of chemicals, steam and solvents consumption by renewable electricity. Biorefinery electrification is employed to improve the efficiency and environmental impact of biomass pretreatment, fermentation and downstream separation and purification stages.

-

Industrial Biotechnology

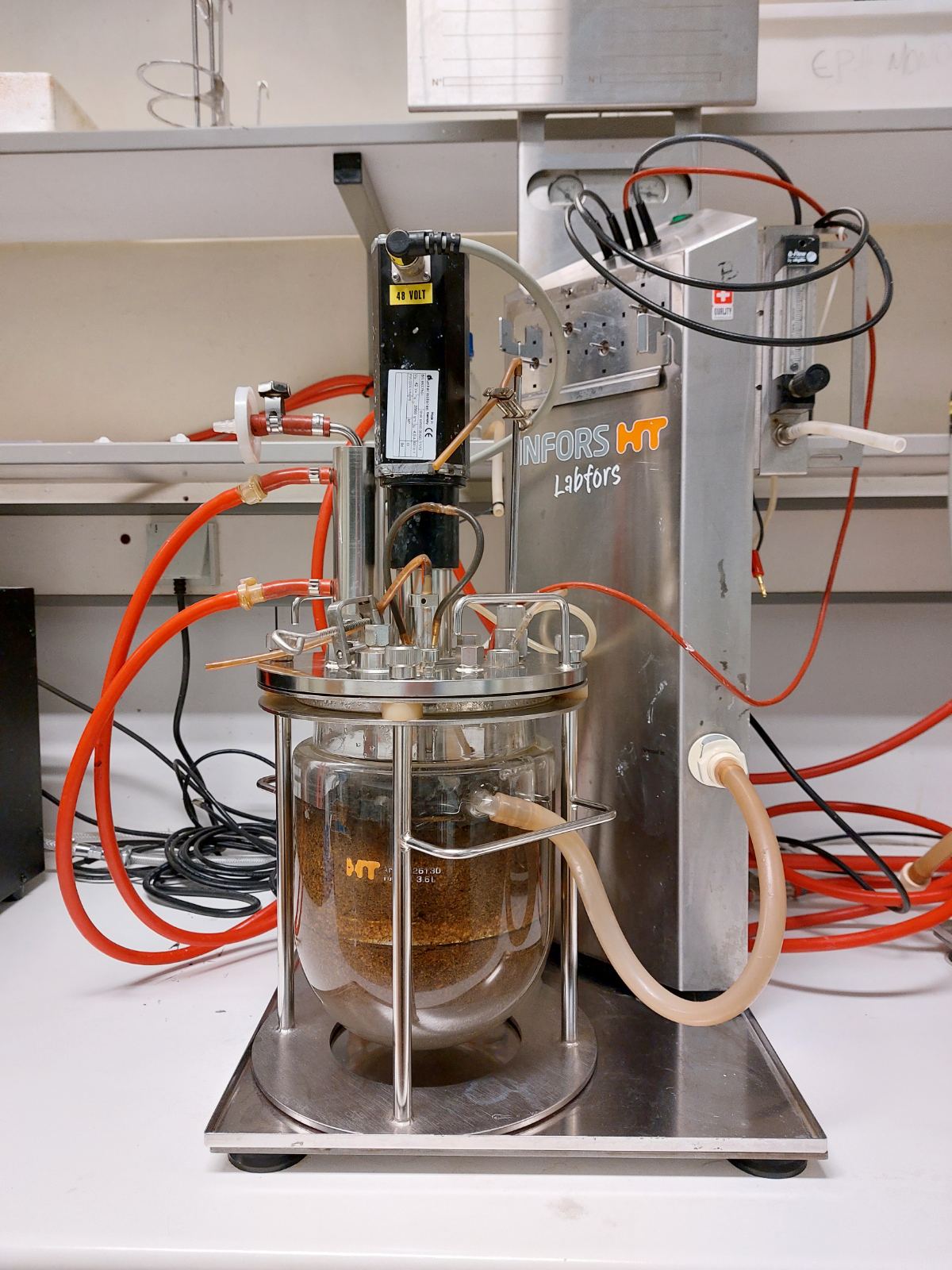

Our research on industrial biotechnology and biochemical engineering focuses on the production of bio-based products from renewable resources. We have expertise in the production of organic acids (e.g. succinic, malic, fumaric, lactic acid), 2,3-butanediol, polyhydroxyalkanoates, microbial oil and bacterial cellulose. Research is also focused on the downstream separation and purification of fermentation products using conventional or novel technologies. Emphasis is given on the evaluation of different end-uses for the fermentation products.

Our bioprocess development scope aims to produce bio-based and sustainable products for diversified industrial sectors, including food, chemical, plastic and agricultural industries. The production of bio-based and biodegradable polymers is combined with their assessment as either rigid or flexible food packaging materials. The production of microbial oil using oleaginous yeast is evaluated for the production of biolubricants, biodiesel and advanced sustainable fuels. Succinic acid has been evaluated in polyurethane production. The food industry could benefit from the production of antimicrobial compounds via fermentation.

-

Novel & Sustainable Technologies

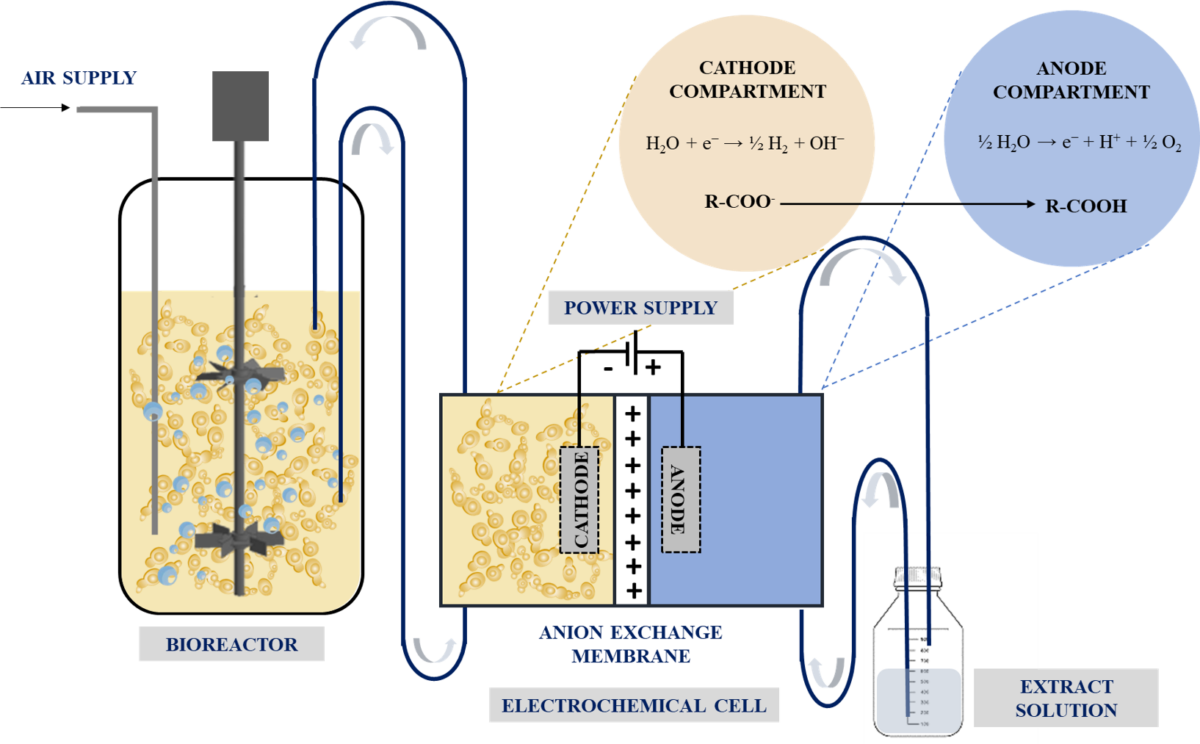

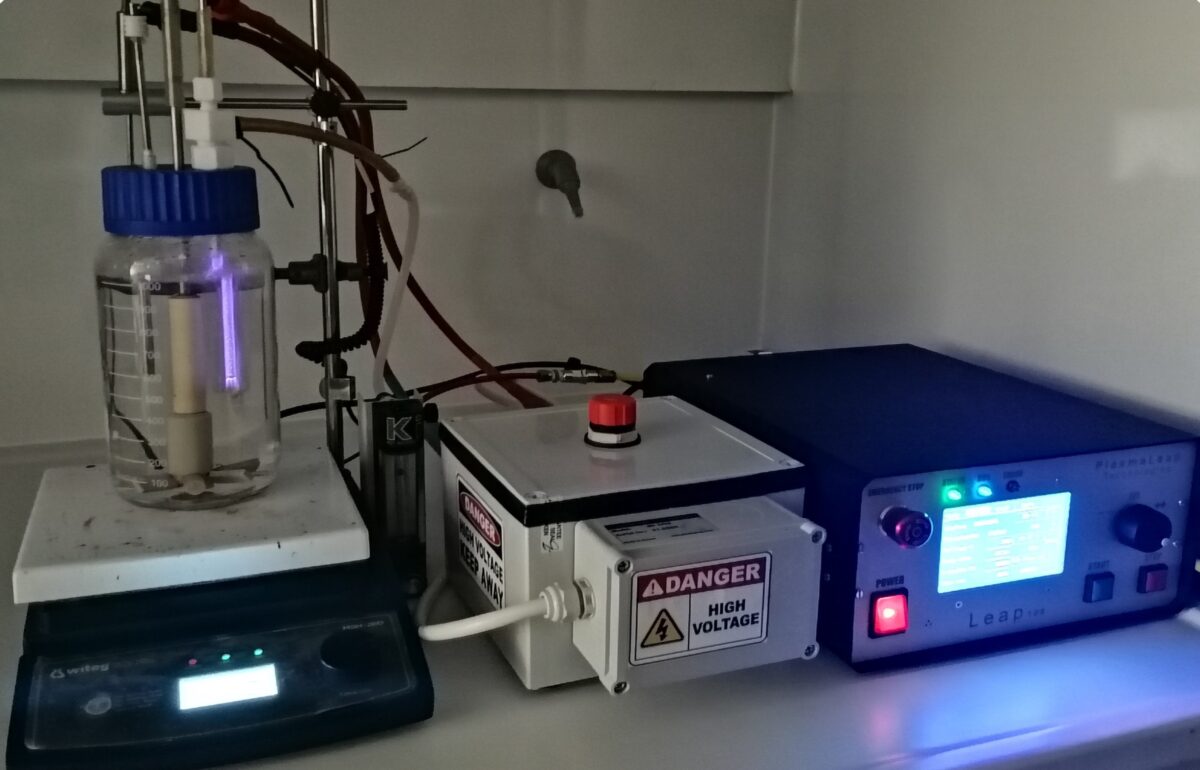

Electrochemical membrane bioreactor

Membrane electrolysis is a novel electrochemical extraction technique in which electrodes are present in the fermentation broth to drive (bio)electrochemical reactions. The electro-motive force drives charged molecules across an anion or a cation exchange membrane. We have used this technology for the separation and purification of organic acids (i.e. succinic acid). The electrochemical cell that consists of a cathode and an anode compartment, separated by an anion exchange membrane, is connected to a bench-top bioreactor. The fermentation broth is recycled through the cathode compartment where organic anions are extracted through the anion exchange membrane into the anode compartment. This technology offers the following advantages:

- Lower metabolic product inhibition during fermentation due to the extraction of organic acids

- Lower neutralizer requirements during fermentations due to OH– generation via water electrolysis

- Improved fermentation efficiency due to either H+ generated via water electrolysis or by direct electron transfer from the cathode electrode

- Reduced unit operations for succinic acid purification due to simultaneous extraction, acidification and concentration of succinic acid in the anode compartment

- Improved environmental impact

Plasma technology

Cold air plasma can be used to modify the lignocellulosic matrix improving the efficiency of enzymatic hydrolysis, offering environmentally friendly and sustainable alternatives to conventional thermochemical processes, as it employs dry gases at atmospheric pressure instead of high temperatures and pressures and use of chemicals.

Dielectric barrier discharge air plasma generates reactive oxygen species (ROS), such as O3, H2O2, and hydroxyl radicals (•OH) and reactive nitrogen species (RNS), such as NO2, NO3–, HNO3, and N2O5. Emission of UV by plasma and ozonolysis have also been widely studied for lignin degradation to facilitate enzymatic hydrolysis of polysaccharides. The combination of UV, •OH, ROS and RNS constitutes an advanced oxidation technology for efficient and sustainable lignocellulose pretreatment.

-

Bio-Based & Biodegradable Polymers Production & Upcycling

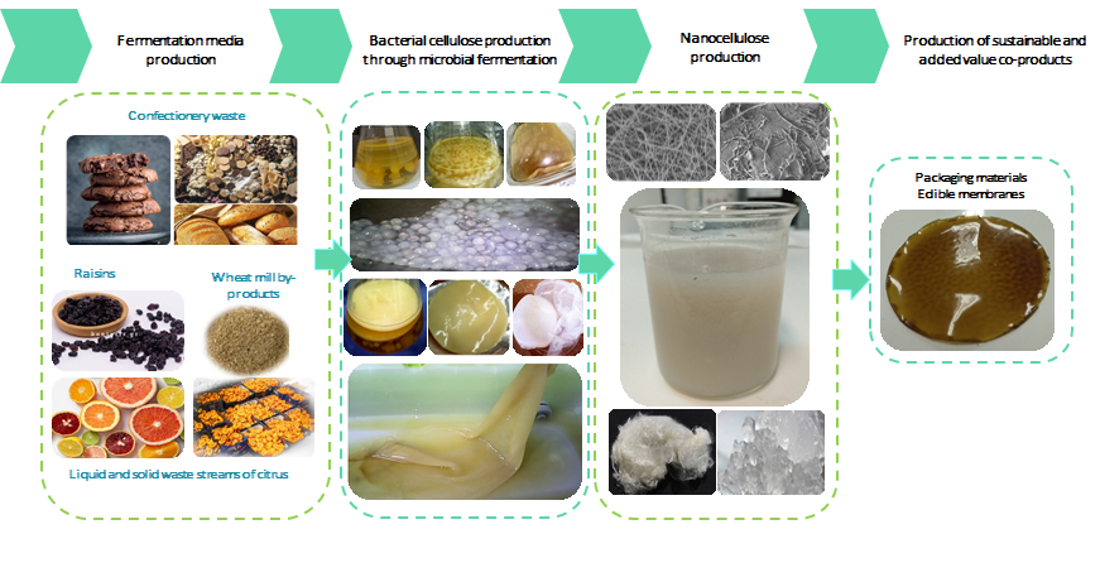

Biopolymer production and upcycling

Bio-based polymers and materials offer sustainable alternatives to traditional petroleum-based plastics, contributing to the mitigation of environmental challenges. Our research focuses on the production and purification of poly(3-hydroxybutyrate) (PHB), poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) and bacterial cellulose via fermentation. Agro-food side streams could be also employed for the extraction of value-added fractions, such as pectin and protein. The bio-based polymers and materials are used for the development of innovative and sustainable food packaging, addressing the increasing demand for environmentally friendly alternatives to conventional plastics.

Poly(3-hydroxybutyrate) and poly(3-hydroxybutyrate-co-3-hydroxyvalerate)

PHB and PHBV are biopolymers synthesized intracellularly by microbial fermentation using crude renewable feedstocks. Biopolymer production, separation and purification is conducted, followed by formulation into packaging materials. PHB and PHBV exhibit thermoplastic properties, enabling their use in different packaging applications, including rigid containers. These biopolymers are biodegradable offering a sustainable solution for single-use packaging applications.

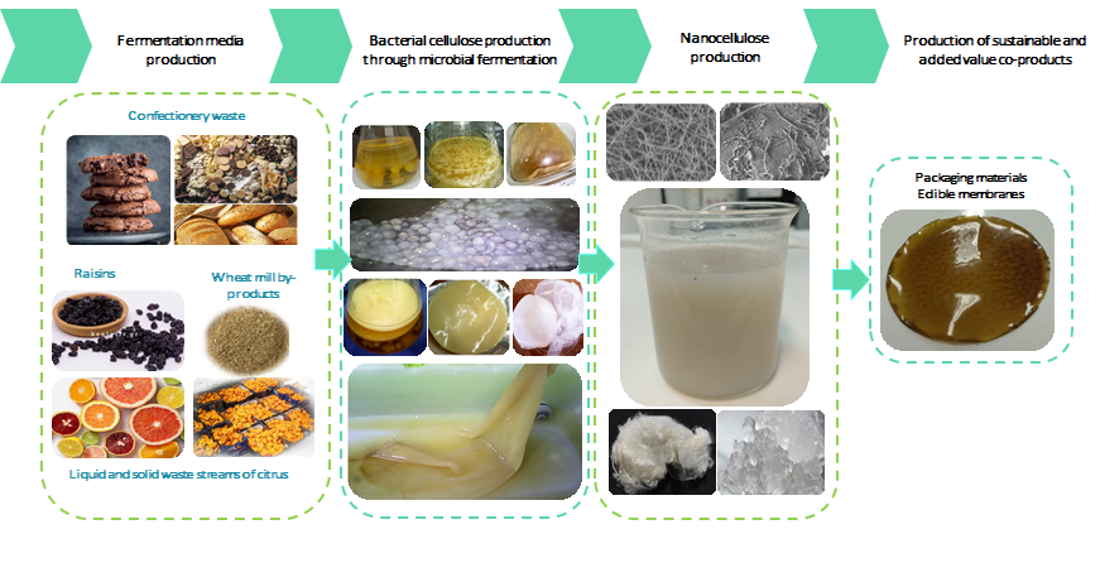

Bacterial cellulose

Bacterial cellulose is a biomaterial produced by acetic acid bacteria via fermentation. Its separation and purification involve washing and it could further convert into nanocellulose by thermochemical or enzymatic processes. Bacterial cellulose has a high degree of polymerization, crystallinity index, modulus of elasticity, tensile strength, thermal stability and water retention capacity. This biomaterial could be used in a wide range of applications, especially as packaging material (films and coatings) and food ingredient (rheology modifier, fat replacer and stabilizer).

Polysaccharides and protein

Pectin is a heterogeneous polysaccharide primarily located in the cell walls of plant cells and serves as a crucial ingredient in the food industry due to its gelling, thickening, and stabilizing properties. Through different extraction techniques, such as hot acid extraction, pectin can be efficiently recovered from different sources (mainly citrus fruits, apples and sugar beet pulp). Pectin recovery is also carried out via more environmentally benign processes, including high-pressure processing, microwave, ultrasound and enzyme-assisted extraction. Pectin-based films can be tailored to possess desirable barrier properties against moisture, oxygen, and microbial activity, making them suitable for various packaging needs. By incorporating antimicrobial agents, antioxidants or pH indicators into pectin matrices, active packaging can extend shelf life, maintain product quality and provide real-time monitoring of food freshness.

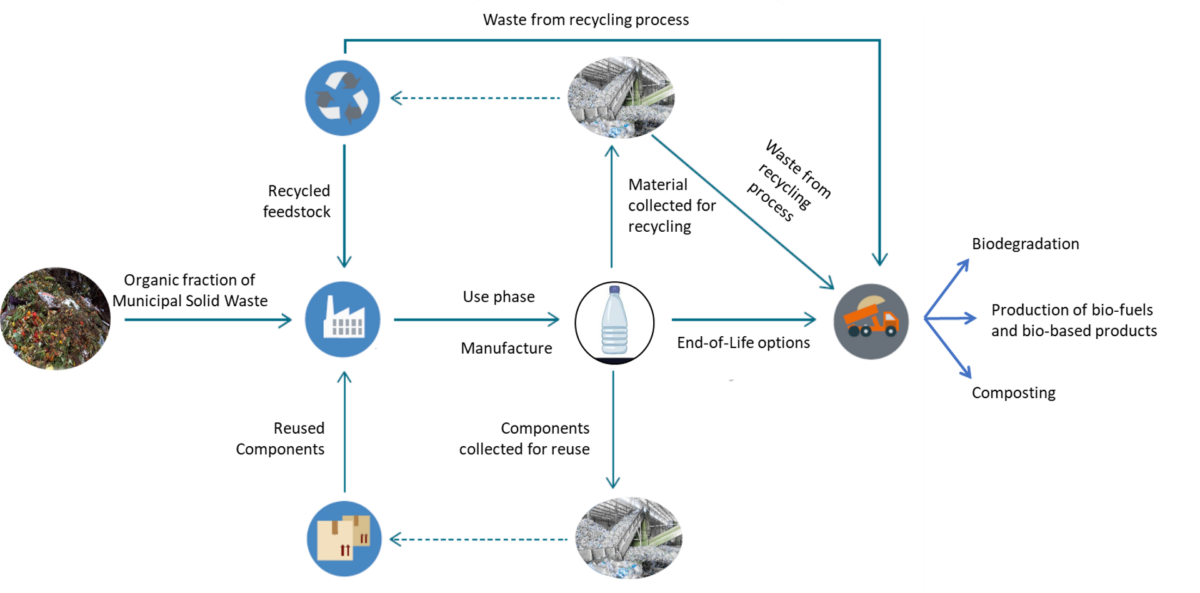

Upcycling of post-consumer bioplastic-based packages

Replacing traditional linear value chains of plastics with sustainable and bio-based polymers necessitates the development of End-of-Life recycling options. Bioplastics for packaging applications will contain various blends of biopolymers such as PHB, PLA and PBS. Chemical, biological or hybrid recycling of post-consumer bioplastics made of various combinations of the above-mentioned biopolymers will result in mixtures of crotonic acid, 3-hydroxyalkanoates, lactic acid, succinic acid and 1,4-butanediol among others. Our research focuses on the chemical, hydrothermal, enzymatic and electrochemical degradation of bioplastics. The produced degradation monomers are used as carbon sources for circular production of fermentation products.

-

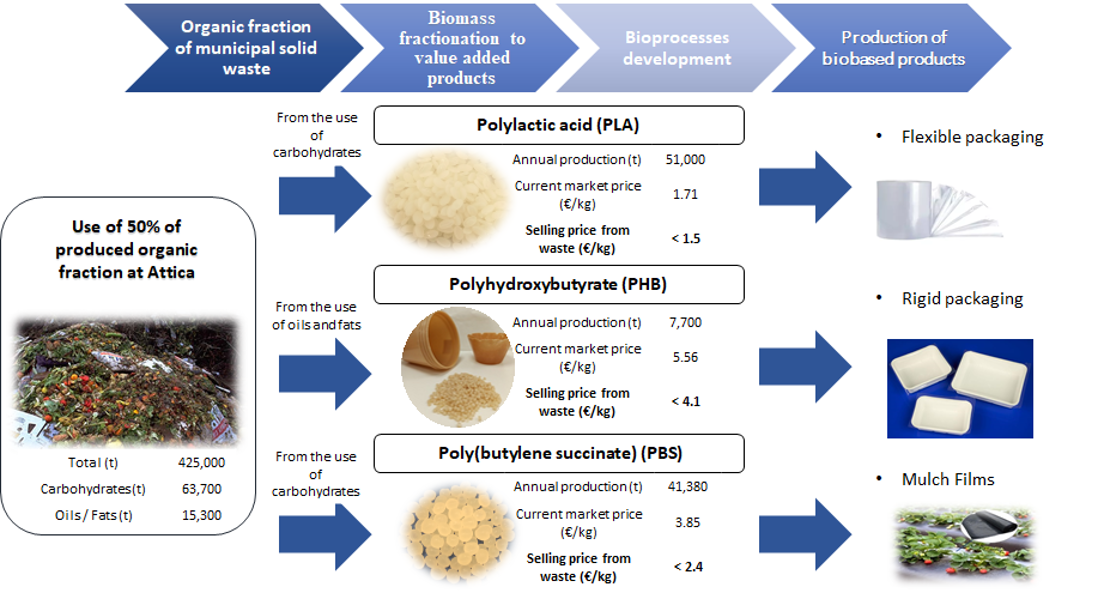

Sustainability Analysis & Circular Bioeconomy

We employ process design using appropriate software (Unisim Honeywell), techno-economic evaluation and life cycle assessment to evaluate the sustainability of biorefineries and bioprocesses. Recent work also focuses on the evaluation of alternative recycling options for the upcycling of post-consumer bioplastics. This approach will minimize the environmental burden caused by their current management practices and facilitate the transition to the bioeconomy era.

Process design is employed for the estimation of material and energy balances that are subsequently used for the estimation of techno-economic indicators, such as production cost and minimum selling price, and environmental indicators. Life Cycle Costing is employed for monetization of environmental externalities. Socioeconomic indicators are also estimated focusing mainly on health and safety, job creation and social justice.

The sustainability of biorefineries could be enhanced by developing circular processes targeting minimal solvent and chemical usage and upcycling of post-consumer bioplastics. Efficient conversion and fractionation of crude renewable resources with selection of appropriate End-of-Life options should be guided by sustainability assessment. We are currently working on the development of sustainability frameworks and assessment models for the production of advanced sustainable biofuels, bio-based chemicals and polymers. Special emphasis is given on the sustainability assessment of food processes and the restructuring of conventional food industries into sustainable biorefineries.